Product Gallery

Discover our full range of products in one place.

Solid Fuel Fired Package Type Steam Boiler

A compact, factory-assembled steam boiler designed to run on solid fuels like coal, wood, or biomass. IBR-certified for compliance with Indian Boiler Regulations, it ensures safe and efficient steam generation for industrial applications. The package design allows quick installation, and the robust construction offers long service life. Ideal for use in food, textile, chemical, and wood-processing industries.

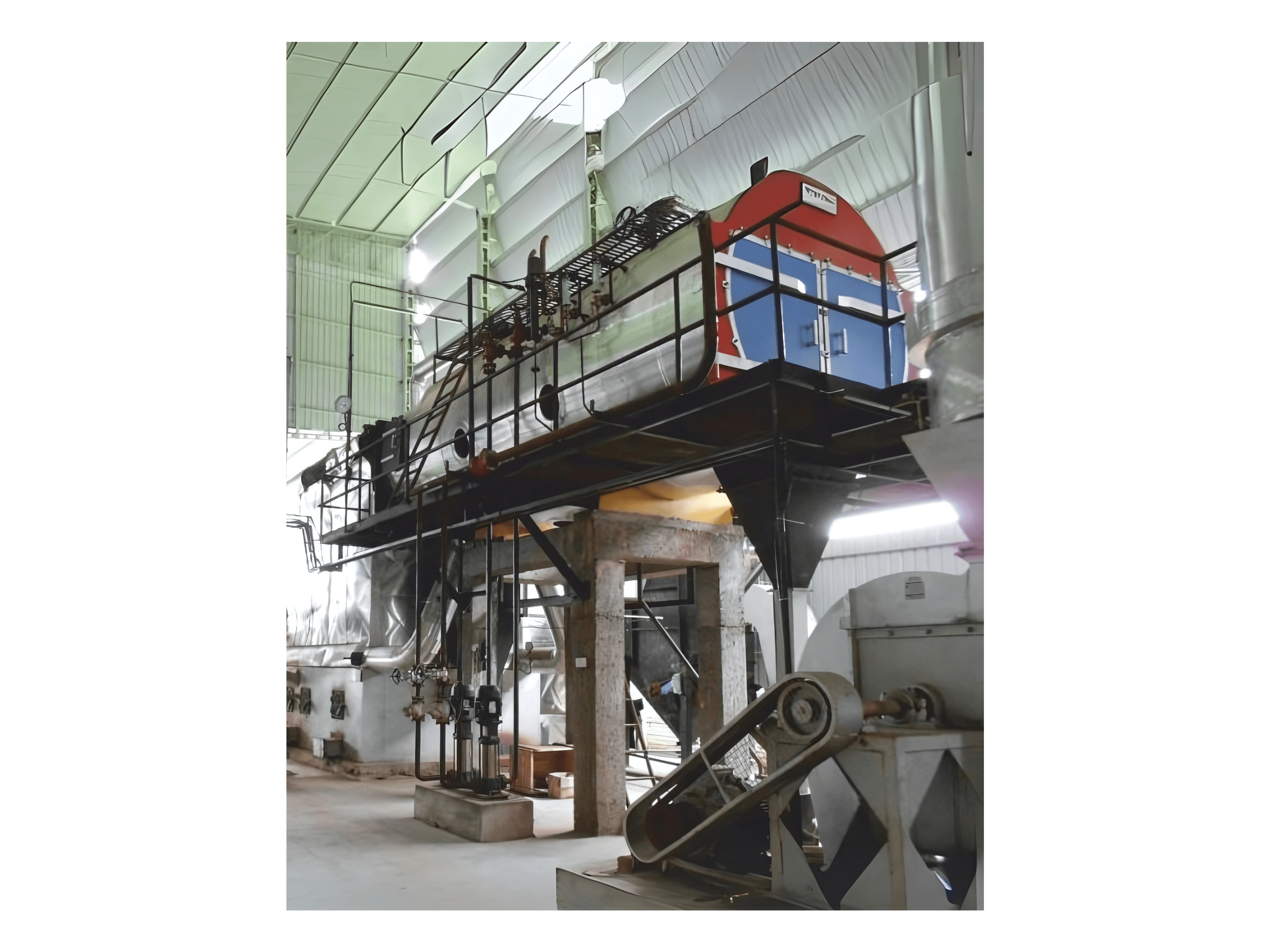

Rice Husk Fired Package Type Drop Feed Boiler

A Rice Husk Fired Package Type Drop Feed Boiler uses rice husk as a renewable fuel to generate steam. It features a compact, pre-assembled design and a drop feed system, where rice husk is dropped into the combustion chamber for efficient burning. This eco-friendly and cost-effective boiler offers high thermal efficiency, making it ideal for industries with access to rice husk as a byproduct.

Water Cum Smoke Tube Type Steam Boiler

A Water Cum Smoke Tube Boiler combines the advantages of both water tube and smoke tube designs, offering high efficiency and reliable steam generation. In this hybrid design, hot flue gases pass through smoke tubes while water surrounds them, with additional water tubes increasing heat transfer. IBR-certified, it meets all statutory safety and quality standards for industrial steam applications. Known for its compact structure, quick start-up, and fuel flexibility, it is ideal for industries such as textiles, food processing, pharmaceuticals, and chemicals.

D-type OIL/GAS Fired Steam Boiler

The D-Type Steam Boiler is a high-efficiency, water tube boiler with a distinctive "D" shape design, where water flows through the tubes and flue gases pass around them. This design provides excellent heat transfer, quick steam generation, and compact construction, making it ideal for high-demand industrial applications. IBR-certified, it meets stringent safety and regulatory standards for steam boilers in India. Known for its durability, fuel efficiency, and reliability, it is commonly used in industries such as power generation, petrochemicals, food processing, and textiles.

Blast Furnace Gas Fired Steam boiler

A Blast Furnace Gas (BFG) Fired Steam Boiler is an industrial boiler system designed to generate steam by utilizing blast furnace gas, a by-product of iron and steel production. This type of boiler plays a critical role in enhancing energy efficiency in steel plants by repurposing low-calorific-value gas that would otherwise be flared or wasted.

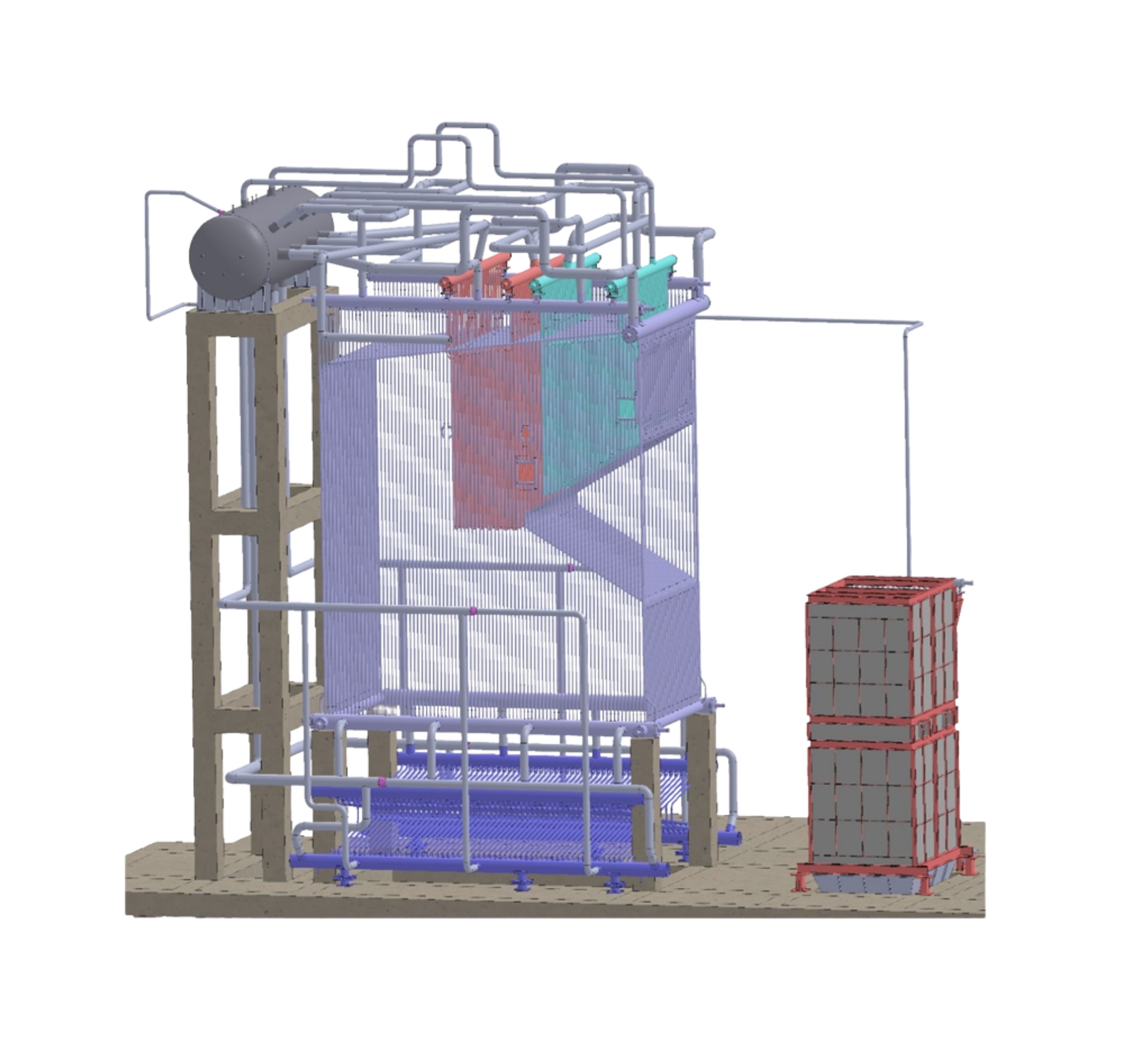

Fully Water Tube Type BI-Drum FBC Steam Boiler

A fluidized bed fired steam boiler uses a bed of solid particles (like sand) suspended by upward-blowing air to burn fuel efficiently. This system ensures better heat transfer, burns low-grade fuels, and reduces emissions. It’s ideal for industries needing fuel flexibility and high combustion efficiency.

TG/RG Fired BI-Drum Steam Boiler

A TG/RG Fired Bi-Drum Steam Boiler is a high-capacity, water-tube boiler that uses Tar Generated (TG) or Refinery Gas (RG) as fuel. It features a bi-drum design (steam and mud drums) for efficient water circulation and is ideal for continuous industrial operations. This boiler is cost-effective, eco-friendly, and reliable, especially in refineries or plants using waste gases as fuel.

Single Durm High Pressure Steam Boiler

A bi-drum boiler is a type of water tube boiler with two drums – a steam drum on top and a mud drum at the bottom. Designed for high-pressure steam generation, it features water-filled tubes heated externally by combustion gases. IBR certification ensures it meets Indian safety and quality standards. It's highly efficient, suitable for a wide range of fuels, and commonly used in power plants, sugar mills, and process industries.