Product Gallery

Discover our full range of products in one place.

TG/RG Fired BI-Drum Steam Boiler

A TG/RG Fired Bi-Drum Steam Boiler is a high-capacity, water-tube boiler that uses Tar Generated (TG) or Refinery Gas (RG) as fuel. It features a bi-drum design (steam and mud drums) for efficient water circulation and is ideal for continuous industrial operations. This boiler is cost-effective, eco-friendly, and reliable, especially in refineries or plants using waste gases as fuel.

Single Durm High Pressure Steam Boiler

A bi-drum boiler is a type of water tube boiler with two drums – a steam drum on top and a mud drum at the bottom. Designed for high-pressure steam generation, it features water-filled tubes heated externally by combustion gases. IBR certification ensures it meets Indian safety and quality standards. It's highly efficient, suitable for a wide range of fuels, and commonly used in power plants, sugar mills, and process industries.

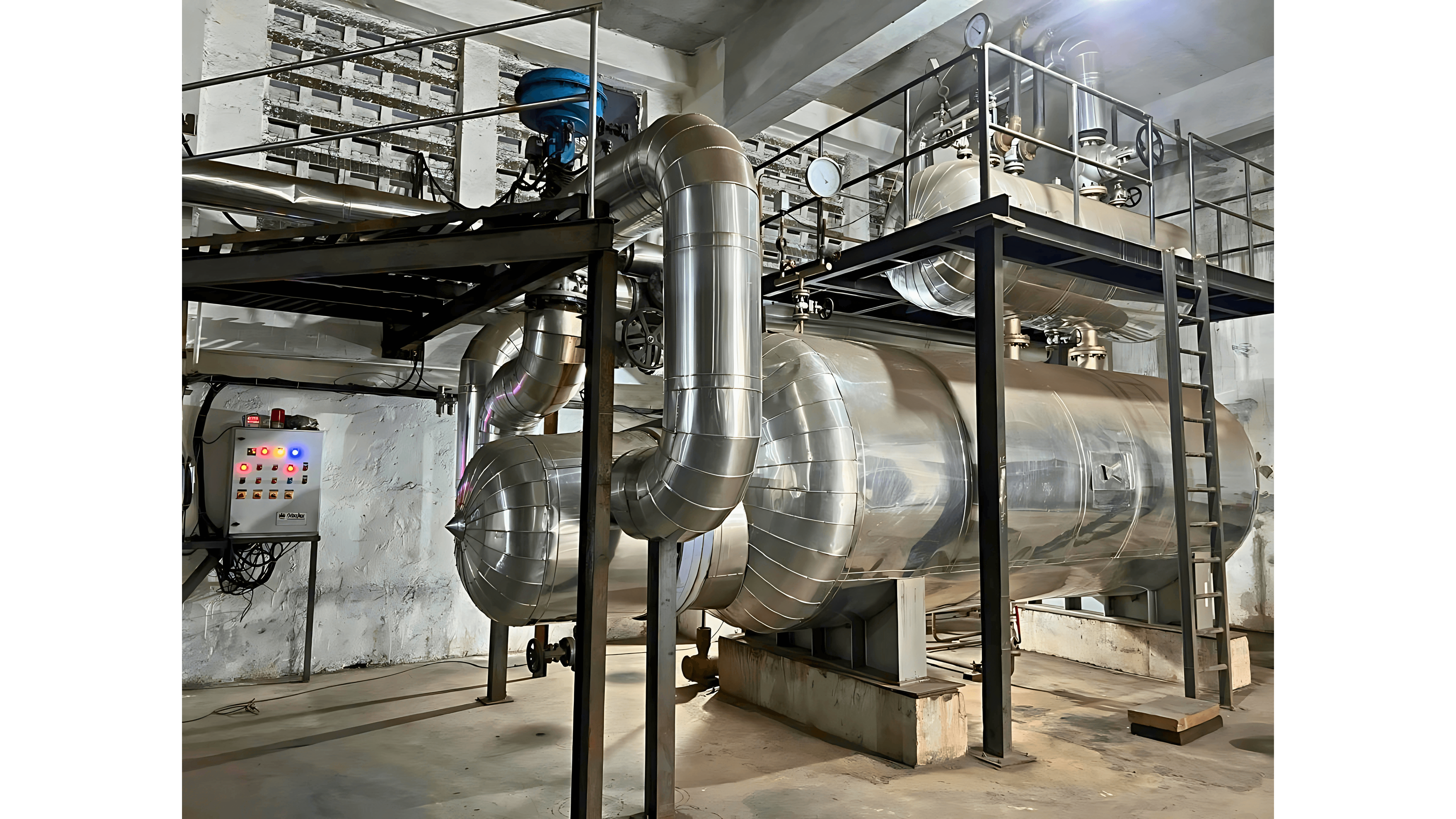

Thermic Fluid Heated Steam Generator

A Thermic Fluid Heated IBR Steam Generator uses hot thermal oil (thermic fluid) to indirectly generate steam. The thermic fluid, heated in a separate heater, flows through coils in the steam generator to convert water into steam. It’s IBR-approved, meaning it meets Indian Boiler Regulations for safety and design. This system is efficient, flame-free at the steam side, and ideal for high-temperature, sensitive operations.

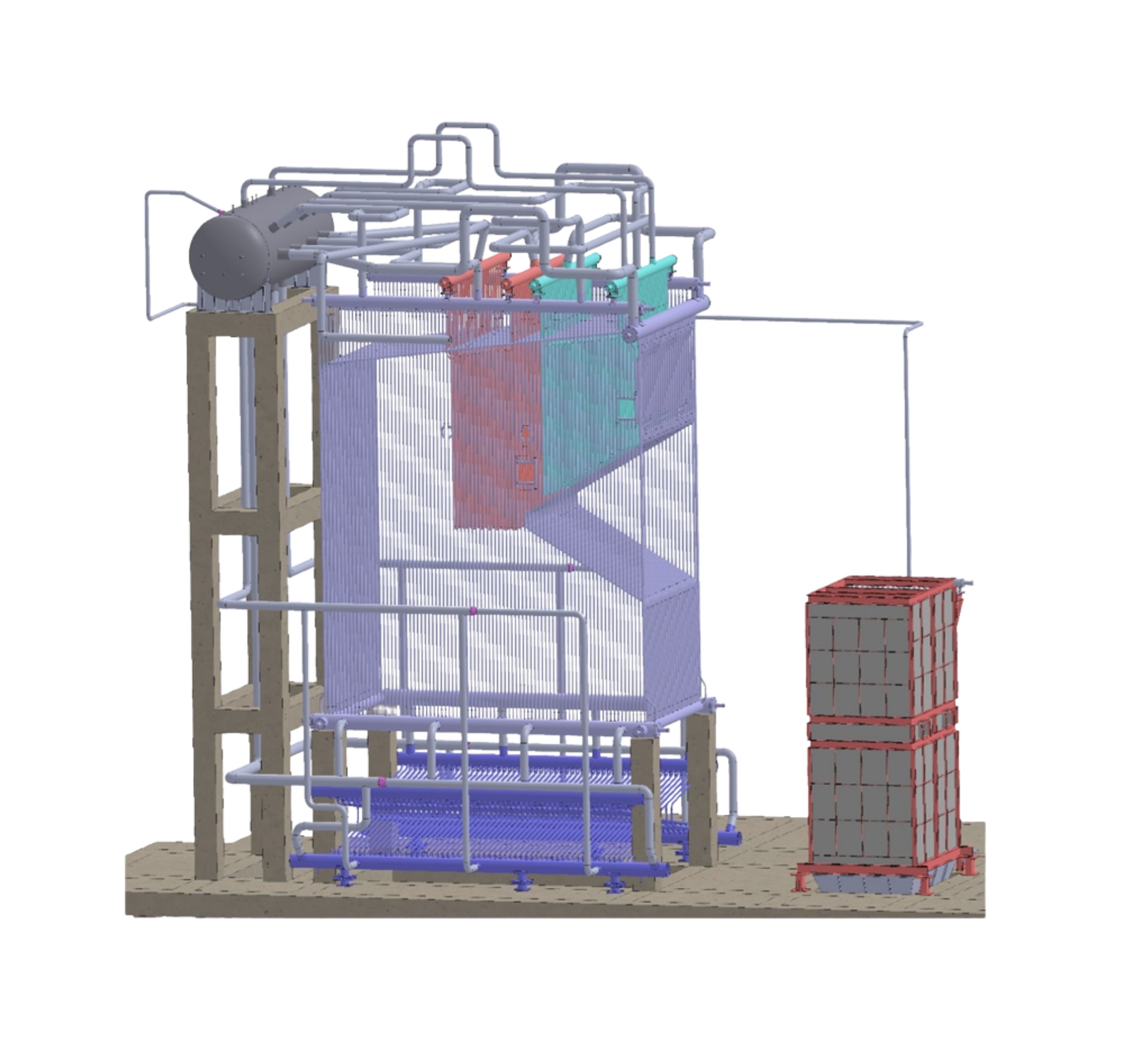

Waste Heat Recovery Steam Boiler

A Waste Heat Recovery IBR Steam Boiler uses waste heat from industrial processes (like engine or furnace exhaust) to generate steam, reducing fuel consumption and improving energy efficiency. It complies with Indian Boiler Regulations (IBR) and helps lower emissions, making it both cost-effective and environmentally friendly.

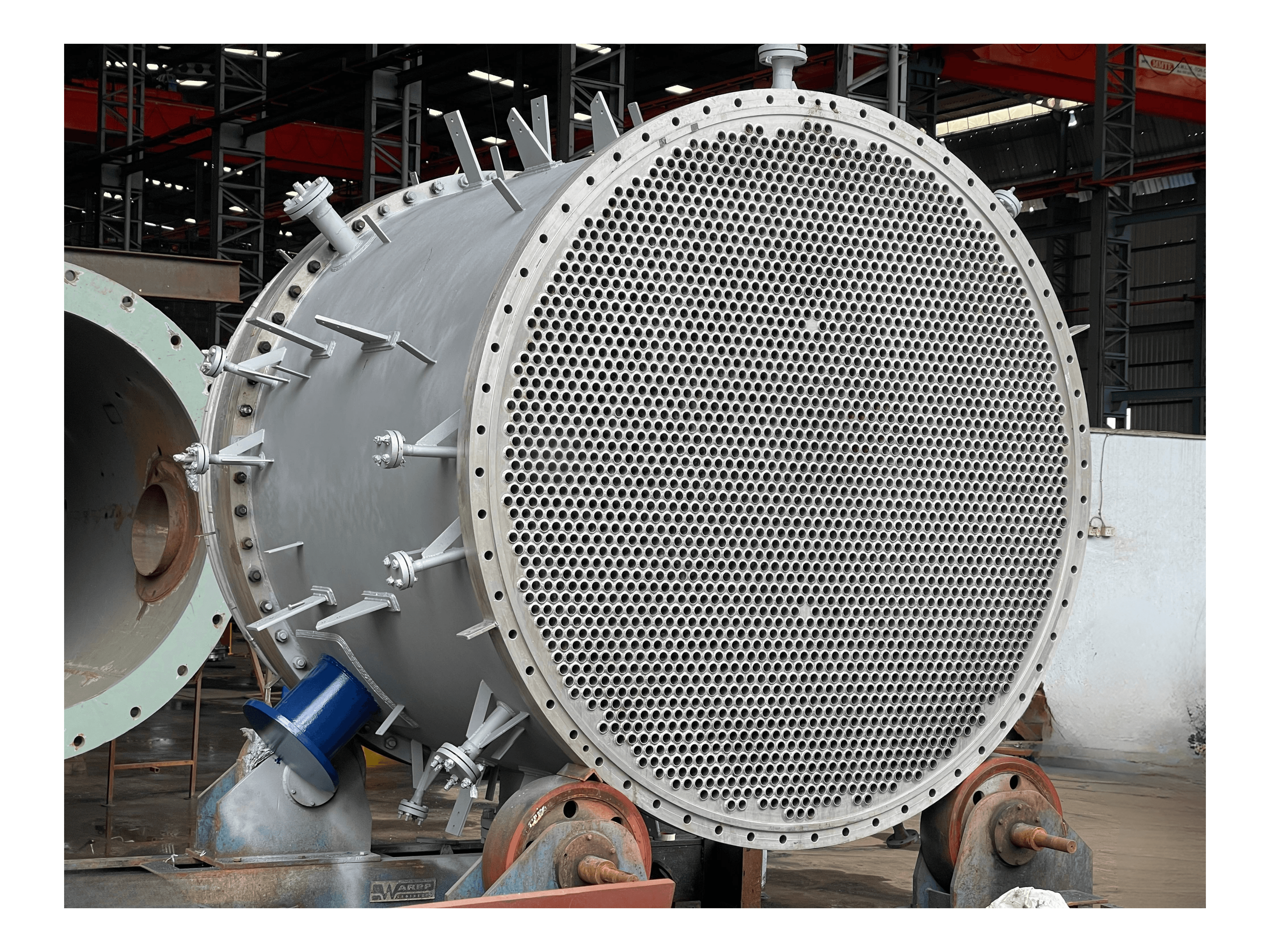

Pressure Vessel

HEATEX is the trusted Partners in the field of custom design and fabrication of ASME pressure vessels. Built to your exact specifications, Each and every Pressure Vessel is designed and fabricated in accordance with ASME and receives thorough inspection by both our In-house Quality Team and an authorized third party inspector of Client.